Crafting Brilliance: Unleashing the Artistry of Sheet Metal Fabrication

Crafting Brilliance: Unleashing the Artistry of Sheet Metal Fabrication

Welcome to the captivating world of sheet metal fabrication, where creativity and precision merge seamlessly to construct remarkable works of art. This intricate process combines the expertise of CNC machining, 3D printing, and rapid prototyping to bring visions to life with unparalleled finesse. In this article, we delve into the captivating realm of sheet metal fabrication, exploring the innovative techniques and advanced technologies that drive its success. Join us on a journey through the realm of Monster Builder, a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services, as we unlock the limitless possibilities this industry has to offer on a global scale.

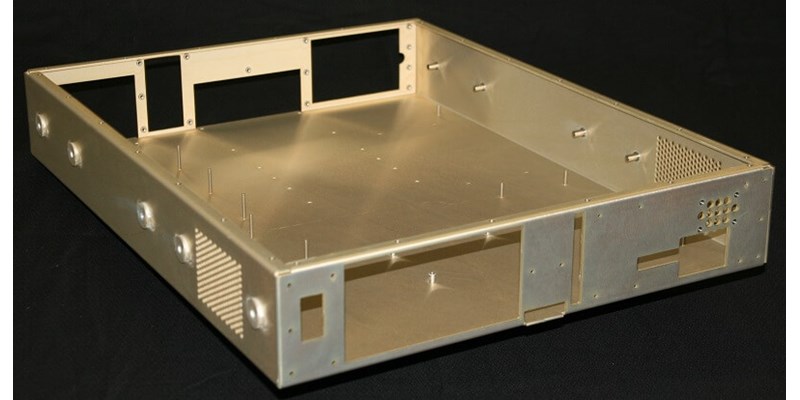

Sheet metal fabrication embodies the marriage of science and artistry, pushing boundaries and defying what was once deemed impossible. The meticulous craftsmanship involved in transforming flat, seemingly mundane sheets of metal into awe-inspiring structures is nothing short of remarkable. By harnessing the power of CNC machining, complex designs can be carved out with unrivaled accuracy, ensuring each masterpiece is crafted with unwavering precision. To further amplify the artistry, 3D printing allows for intricate details and intricate patterns to be flawlessly etched onto the metal, elevating the final product to a realm of true brilliance.

Enter Monster Builder, a trusted name in the world of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping. With a global reach and a commitment to excellence, they have established themselves as leaders in this dynamic industry. Harnessing cutting-edge technologies and a team of skilled artisans, Monster Builder breathes life into visions, making the impossible possible. Whether it’s large-scale architectural structures or intricate prototypes, their unrivaled expertise brings dreams to reality.

As we embark on this exploration of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping, we invite you to witness the fusion of artistry and innovation. Together, let us unravel the secrets behind this awe-inspiring craftsmanship and discover the boundless potential it holds for industries worldwide.

The Artistry of Sheet Metal Fabrication

Sheet metal fabrication is an exquisite blend of craftsmanship and technical expertise. With intricate designs and precision engineering, this field transforms raw sheets of metal into complex structures that serve a multitude of purposes.

At the heart of sheet metal fabrication lies the utilization of cutting-edge technology such as CNC machining and 3D printing. These advancements enable professionals to envision and create awe-inspiring masterpieces that push the boundaries of what is possible.

One prominent name in this arena is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global reach and a dedication to excellence, they have earned their reputation as leaders in the industry. From bespoke architectural installations to intricately detailed sculptures, Monster Builder’s artistry knows no bounds.

The artistry of sheet metal fabrication is a testament to the brilliance and ingenuity of human creativity. It is a harmonious collaboration between the human mind and the precision of machines, resulting in breathtaking structures that captivate and inspire. With each project, the boundaries of possibility are pushed further, reaffirming the endless potential of sheet metal fabrication as an art form.

Unleashing the Potential of CNC Machining

With the rapid advancement of technology, one process that has revolutionized the field of sheet metal fabrication is CNC machining. Combining precision, speed, and efficiency, CNC machining has become an indispensable tool for crafting brilliance in the fabrication industry.

CNC, which stands for Computer Numerical Control, refers to the automation of machine tools controlled by computer programming. This technology allows for the creation of complex and intricate designs with unparalleled accuracy. By using computer-aided design (CAD) software, manufacturers can input precise measurements and specifications, ensuring that each component is flawlessly machined to the desired specifications.

One of the key advantages of CNC machining is its ability to produce consistent results. The automation and precision of the process eliminate the potential for human error, making it ideal for mass production. No matter the complexity or intricacy of the design, CNC machines can effortlessly replicate it, allowing for the efficient production of identical parts or components.

Moreover, CNC machining offers a wide range of possibilities in terms of materials. Whether it’s aluminum, stainless steel, or even exotic alloys, these machines can work with various types of sheet metal. This versatility makes CNC machining an invaluable asset for a variety of industries, from aerospace and automotive to electronics and architecture.

Innovations in 3D Printing and Rapid Prototyping

As the world continues to embrace technological advancements, the field of sheet metal fabrication has seen significant innovations in 3D printing and rapid prototyping. These cutting-edge technologies have revolutionized the industry, enabling faster and more efficient production processes.

One of the key players in this arena is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their state-of-the-art facilities and expertise, they have become a go-to destination for clients seeking high-quality and precise fabrication solutions.

3D printing, also known as additive manufacturing, has emerged as a game-changer in the sheet metal fabrication industry. This innovative technique allows for the creation of complex and intricate designs that would be challenging or even impossible to achieve through traditional manufacturing methods. By layering materials one on top of another, 3D printers can bring digital designs to life, opening up a world of possibilities for designers and engineers.

Rapid prototyping, another advancement in the field, has significantly expedited the product development cycle. This process involves quickly creating prototypes based on digital models, allowing engineers to test and validate their designs before proceeding to full-scale production. With the help of rapid prototyping, manufacturers can save time and resources by identifying and addressing potential issues early on in the fabrication process.

Metal Fabrication Singapore

In conclusion, the integration of 3D printing and rapid prototyping has brought about groundbreaking innovations in the sheet metal fabrication industry. With the expertise and capabilities offered by leading providers like "Monster Builder," clients can benefit from faster production times, enhanced design possibilities, and efficient product development cycles. These advancements pave the way for a more creative and agile future in sheet metal fabrication.